Our Capabilities

Knife Cutting

Mercer Gasket & Shim’s highly accurate, state-of-the-art knife cutting capabilities allow us to deliver products to customers when speed, flexibility, and convenience are important.

Learn More Laser CuttingLaser Cutting

Specializing in fast turnaround of thin-gauge components, Mercer Gasket & Shim offers world-class laser cutting services for applications where precision is a high priority and quality is essential.

Learn More Waterjet CuttingWaterjet Cutting

Mercer Gasket & Shim’s waterjet cutting service offers a fast, flexible, and accurate method for fabricating complex or difficult parts while maintaining the integrity of the material.

Learn More Flatbed Die CuttingFlatbed Die Cutting

Our high-speed, Flatbed die-cutting can be used to create a variety of components, such as gaskets, packaging, bumpers, dampeners, labels, printed products, and more.

Learn More CNC Router CuttingCNC Router Cutting

Mercer Gasket & Shim is equipped with new, state-of-the-art router cutting equipment. We can assist with mid to high volume mass production runs.

Learn More

Mercer Gasket & Shim is proud to offer Kroll and Ziller advanced sealing solutions. Our staff of experienced sealing and gasketing experts can help you to select the right seal for your requirements. Keep reading to learn more about K&Z seals, or if you want assistance now send an

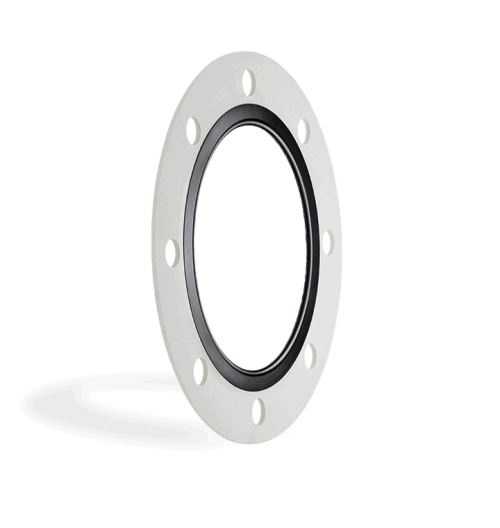

Mercer Gasket & Shim is proud to offer Kroll and Ziller advanced sealing solutions. Our staff of experienced sealing and gasketing experts can help you to select the right seal for your requirements. Keep reading to learn more about K&Z seals, or if you want assistance now send an  Kroll & Ziller’s rubber-steel flange gaskets serve as dependable solutions for creating secure seals in a wide range of pipeline construction applications. These gaskets are particularly well-suited where a reliable seal with minimal surface pressure is essential.

Kroll & Ziller’s rubber-steel flange gaskets serve as dependable solutions for creating secure seals in a wide range of pipeline construction applications. These gaskets are particularly well-suited where a reliable seal with minimal surface pressure is essential. G-ST-P/ISO seals excel in preventing corrosion, especially in scenarios where different flange materials are paired, such as steel and stainless-steel flanges. In such cases, electrochemical corrosion can occur, necessitating the electrical isolation of these materials to prevent the creation of a galvanic element. To address this concern, we employ the G-ST-P/ISO seal kit. While its structural design is in line with our G-ST-P/KN seal kit, it diverges in the choice of materials. Instead of steel or stainless steel, we use electrically insulating materials like PP/PE, UPGM 203, or EP GC 203. These insulating materials are combined with a sealing lip made from one of our elastomers. The seal kit also includes bolt insulation, comprising an insulating tube constructed from a coated glass fabric tube (Mylar/glass silk) and insulating washers made from EP GC 203.

G-ST-P/ISO seals excel in preventing corrosion, especially in scenarios where different flange materials are paired, such as steel and stainless-steel flanges. In such cases, electrochemical corrosion can occur, necessitating the electrical isolation of these materials to prevent the creation of a galvanic element. To address this concern, we employ the G-ST-P/ISO seal kit. While its structural design is in line with our G-ST-P/KN seal kit, it diverges in the choice of materials. Instead of steel or stainless steel, we use electrically insulating materials like PP/PE, UPGM 203, or EP GC 203. These insulating materials are combined with a sealing lip made from one of our elastomers. The seal kit also includes bolt insulation, comprising an insulating tube constructed from a coated glass fabric tube (Mylar/glass silk) and insulating washers made from EP GC 203. Rubber and steel profile seals with an open insert offer an ideal solution for situations where a standardized seal is not suitable. Thanks to their innovative design principle, these profile seals can be customized to accommodate a wide range of diameters and geometries, perfectly tailored to meet the specific needs of each customer.

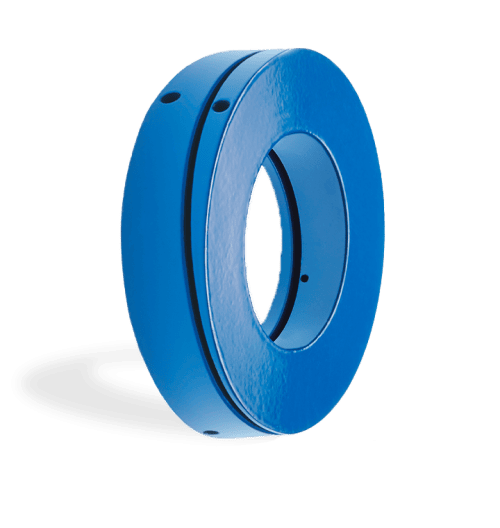

Rubber and steel profile seals with an open insert offer an ideal solution for situations where a standardized seal is not suitable. Thanks to their innovative design principle, these profile seals can be customized to accommodate a wide range of diameters and geometries, perfectly tailored to meet the specific needs of each customer. The G-ST wedge rings are composed of two shells and a rubber seal, which also holds certification for use with drinking water. These rings serve the purpose of facilitating adjustments during assembly, allowing for the convenient correction of misalignments or excessive gaps between flange blades. The G-ST wedge ring offers a continuous adjustment range from 0° to 8°, enabling the modification of the pipeline’s route without the need for additional, intricate welding procedures.

The G-ST wedge rings are composed of two shells and a rubber seal, which also holds certification for use with drinking water. These rings serve the purpose of facilitating adjustments during assembly, allowing for the convenient correction of misalignments or excessive gaps between flange blades. The G-ST wedge ring offers a continuous adjustment range from 0° to 8°, enabling the modification of the pipeline’s route without the need for additional, intricate welding procedures.